|

||||||||||||||||

H20 concrete formwork beams of SPRUCE and FIR. H20 concrete formwork beams of SPRUCE and FIR.

|

||||||||||||||||

| PROPERTIES |

Cheaper and high quality product for formwork Cheaper and high quality product for formwork Excellent flexural strength Excellent flexural strength Minimal distortion Minimal distortion Waterproof and water resistant Waterproof and water resistant Comes from sustainably managed European forests (FSC) Comes from sustainably managed European forests (FSC)

|

|||||||||||||||

| MATERIAL | SPRUCE and FIR | |||||||||||||||

| DRYING | KD 12 +/- 2% | |||||||||||||||

| WEIGHT | 4,7Kg/m | |||||||||||||||

| BOND | Hot glue, melamine resin meets the requirements of EN 301 for bonding fingerjoints | |||||||||||||||

| WINGS |

• Made of Spruce or Fir, carefully selected • The wing and the core are assembled by a joint splice and are bonded crosswise (relative to the rings) • the cross dimensions are 80 x 40 mm • The wings can be joined together in length • The wing is milled along its core • The edges of the wing are planed and chamfered (up to about 0.4 mm) |

|||||||||||||||

| CORE | 3 layered Plywood plate bonded so that the rings are vertical (relative to the cross section) | |||||||||||||||

| CERTIFICATIONS |

DIN EN 13377 ; FSC

|

|||||||||||||||

| TREATEMENT | The surface is completely protected by a waterproof and water-repellent coating | |||||||||||||||

| ADAPTABILITY | With 3 layers in the core, the H20 beams can be cut to any length, without their properties being altered. | |||||||||||||||

| STANDARD LENGTHS | 1,95 / 2,45 / 2,65 / 2,90 / 3,30 / 3,60 / 3,90 / 4,50 / 4,90 / 5,90 / maximum length: 6,00 m | |||||||||||||||

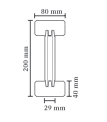

DIMENSIONS AND DEVIATIONS

|

|

|||||||||||||||

| TECHNICAL CHARACTERISTICS | ||||||||||||||||

The values shown are valid for new formwork beams that have not yet been used, stored in suitable and properly used conditions. For beams which have been used several times, it is necessary (depending on different uses and requirements thereof) adding a proportional safety factor. |

||||||||||||||||

| PACKING |

• By full container of 4600 ml • By full truckload of 5000 ml |

|||||||||||||||

TRUCK PACKING

|

• Standard Package 50 pieces / package • Ready for immediate use on site • Parcels placed on wooden slats that protect joists and allow you to move easily with a forklift |

|||||||||||||||

CONTAINER PACKING

|

• Standard Package 100 pieces / package • Ready for immediate use on site • Parcels placed on wooden slates that protect joists and allow you to move easily with a forklift |

|||||||||||||||

| DELIVERY LEAD TIME | Within 3 weeks after the client has made the request | |||||||||||||||

| APPLICATIONS | BPW & CONCRETE FORMWORK– all kinds of construction with concrete | |||||||||||||||

|

|

||||||||||||||||

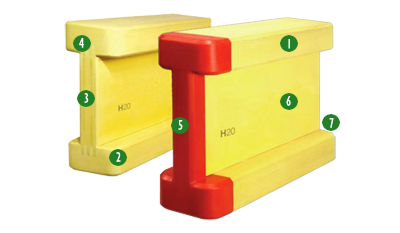

The wing is made of carefully selected quality wood.

The wing is made of carefully selected quality wood.  The core consists of a 3-layer panel, which ensures the stability of the beam and allows it to withstand all weather conditions.

The core consists of a 3-layer panel, which ensures the stability of the beam and allows it to withstand all weather conditions. Wing assemblies and core are inseparably joined by a splice.

Wing assemblies and core are inseparably joined by a splice. Optional: plastic protective cap, shock resistant. Placed at the ends of the beam, this adapter provides additional protection against mechanical damage. This allows the beam to be reused several times and prolongs the beam’s life span while improving it’s strength.

Optional: plastic protective cap, shock resistant. Placed at the ends of the beam, this adapter provides additional protection against mechanical damage. This allows the beam to be reused several times and prolongs the beam’s life span while improving it’s strength. The surface of the beams is protected by a waterproof coating which guarantees a long lifespan.

The surface of the beams is protected by a waterproof coating which guarantees a long lifespan. For greater ease of use, the length is indicated on each beam (beams are 20cm high and are produced in various standard lengths).

For greater ease of use, the length is indicated on each beam (beams are 20cm high and are produced in various standard lengths).

Birch

Birch