|

||||||||||||||||||||||

|

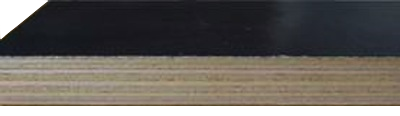

The COMBI filmed plywood offers a very interesting economical solution for concrete formwork. It’s core is composed of a mixture of two different species – shown in the composition section below. In this way you can make the best trade-off between price and quality to get panel specifications to match your concrete formwork needs. Chinese factories that produce COMBI filmed plywood are very flexible and can provide panels specially adapted to the technical characteristics sought.

The core of these panels will therefore either be composed of: • Poplar (450 kg/m3) + Eucalyptus (650 kg/m3) = 550 kg/m3 |

||||||||||||||||||||||

FILM TYPES  Imported brown Films, or black local films. Weight : 120 g/m2 ou 240 g/m2. Different types of possible films, on demand Imported brown Films, or black local films. Weight : 120 g/m2 ou 240 g/m2. Different types of possible films, on demand

|

Face : Smoothe Phenolic Dynea Film 120 g/m2 Quality A Dark Brown Counter-Face : Smoothe Phenolic Dynea Film 120 g/m2 Quality A Dark Brown |

|||||||||||||||||||||

| COMPOSITION | A MIX OF 2 MATERIALS OF YOUR CHOICE | |||||||||||||||||||||

|

|

||||||||||||||||||||||

| GRAIN |

Crossed grain  Long grain on demand Long grain on demand

|

|||||||||||||||||||||

| GLUE |

WBP (phenolic – class 3 – exterior) according to the EN 314-3 standard E1 very low formaldehyde emissions  other bonds available on demand other bonds available on demand

|

|||||||||||||||||||||

| EDGE PROTECTION | 4 treated edges waterproof acrylic paint (color film) | |||||||||||||||||||||

| AVERAGE DENSITY | Dependent on the choice of materials used to make the plywood | |||||||||||||||||||||

| CERTIFICATIONS |

CE 2+ Marking (CE S structure) structural applications according to the EN 13986 standard ; FSC

|

|||||||||||||||||||||

| STANDARD FORMATS |

1250×2500 ; 1200×2500 ; 1220×2440 ; 600×2500 ; 3000×1500 mm

|

|||||||||||||||||||||

|

||||||||||||||||||||||

| PACKING | By full container of approximately 45m3 | |||||||||||||||||||||

All items related to the keyword : Chine

F/F Filmed Combi

F/F Filmed Poplar

|

|||||||||||||||||||

| Plywood filmed in the most economically possible way. Ideal for concrete formwork (easy to work with due to it’s mechanical properties). | |||||||||||||||||||

FILM TYPES  Imported brown films, or local black films. Weight : 120 g/m2 ou 240 g/m2. Different types of films available on demand Imported brown films, or local black films. Weight : 120 g/m2 ou 240 g/m2. Different types of films available on demand

|

FACE : Smoothe Phenolic Dynea Film 120 g/m2 Quality I (dark brown) COUNTER-FACE : Smoothe Phenolic Dynea Film 120 g/m2 Quality I (dark brown) |

||||||||||||||||||

| COMPOSITION | Interior : 100% Chinese POPLAR | ||||||||||||||||||

| GRAIN | Long grain | ||||||||||||||||||

| GLUE |

WBP (phenolic – class 3 – exterior) according to the EN 314-3 standard E1 very low formaldehyde emissions  other bonds available on demand other bonds available on demand

|

||||||||||||||||||

| EDGE PROTECTION | 4 treated edges waterproof acrylic paint (color film) | ||||||||||||||||||

| AVERAGE DENSITY | 450 kg/m3 | ||||||||||||||||||

| CERTIFICATIONS |

CE 2+ Marking(CE S structure) structural applications according to the EN 13986 standard ; FSC

|

||||||||||||||||||

| STANDARD FORMATS | 2500 x 1250 mm | ||||||||||||||||||

|

|||||||||||||||||||

| PACKING | By complete container of approximately 45m3 | ||||||||||||||||||

W/F Wiremesh Anti-Slip Combi Plywood

|

||||||||||||||||||||||

|

Wiremesh anti-slip COMBI plywood offers a very interesting economic design solution for: scaffolds, platforms, podiums, trailers, etc. Their core is composed of a mixture of two different species –shown in the composition section below. In order to find the best trade-off between price and quality it is important to know the applications of these panels. Chinese factories that produce the wiremesh anti-slip COMBI plywood are very flexible and can provide panels specially adapted to the technical characteristics sought. The core of these panels will therefore either be composed of: • Poplar (450 kg/m3) + Eucalyptus (650 kg/m3) = 550 kg/m3 |

||||||||||||||||||||||

FILMS  different types of films are available on demand with different : Weight (120 g/m2, 240 g/m2), colour, design (grains, hexagons), etc. different types of films are available on demand with different : Weight (120 g/m2, 240 g/m2), colour, design (grains, hexagons), etc.

|

Surface : Wiremesh anti-slip film 120 g/m2 (brown – straight grain) Quality A Counter-Face : Smoothe Dynea Film 120 g/m2 (brown) Quality A |

|||||||||||||||||||||

| COMPOSITION | A MIX OF 2 MATERIALS OF YOUR CHOICE: | |||||||||||||||||||||

|

|

||||||||||||||||||||||

| CONSTRUCTION |

Crossed grain  Long grain, available on demand Long grain, available on demand

|

|||||||||||||||||||||

| GLUE |

WBP (phenolic – class 3 – exterior) according to the EN 314-3 standard E1 very low formaldéhyde emissions  other bonds available on demand other bonds available on demand

|

|||||||||||||||||||||

| EDGE PROTECTION | 4 treated edges waterproof acrylic paint (color film) | |||||||||||||||||||||

| AVERAGE DENSITY | Dependent on the choice of materials used to make the plywood | |||||||||||||||||||||

| CERTIFICATIONS |

CE 2+ Marking (CE S structure) structural applications according to the EN 13986 standard ; FSC

|

|||||||||||||||||||||

| STANDARD FORMATS | 1250×2500 ; 1200×2500 ; 1220×2440 ; 600×2500 ; 3000×1500 mm | |||||||||||||||||||||

|

||||||||||||||||||||||

| PACKING | By containers of approximately 45m3 | |||||||||||||||||||||

Scots Pine BB / BB (II / II)

|

||||||||||||||||||||||||||||||||||

| The Scots pine plywood from China BB / BB is one of the flagship products of our range! It is indeed the result of a longstanding collaboration with a Chinese factory, having learned (under our supervision) to produce a quality equivalent to a Russian sorting “II / II”. This panel is adorned with two beautiful surfaces sanded, solid and flat, allowing it to be varnished or painted. This is a very economical product for applications that require it’s structural (CE 2+) aesthetic qualities. | ||||||||||||||||||||||||||||||||||

| QUALITY OF THE FACES |

BB = II Face may display some small sound knots, and some occasional small repairs. Sanded. / BB = II Face may display some small sound knots, and some occasional small repairs. Sanded. / BB = II Face may display some small sound knots, and some occasional small repairs. Sanded.

|

|||||||||||||||||||||||||||||||||

| COMPOSITION | Interior 100% Chinese SCOTS PINE | |||||||||||||||||||||||||||||||||

| GRAIN | Long grain | |||||||||||||||||||||||||||||||||

| GLUE | WBP (phenolic – class 3 – exterior) according to the EN 314-3 standard E1 very low formaldehyde emissions | |||||||||||||||||||||||||||||||||

| AVERAGE DENSITY | 540 kg/m3 | |||||||||||||||||||||||||||||||||

| CERTIFICATIONS |

CE 2+ Marking(CE S structure) structural applications according to the EN 13986 standard ; FSC

|

|||||||||||||||||||||||||||||||||

| STANDARD FORMATS |

2500×1250 ; 2440×1220 ; 2400×1200 mm

|

|||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||

| PACKING | By full truckload of approximately 45m3 | |||||||||||||||||||||||||||||||||

Birch

Birch